The Belt Dryer that Sets New Standards

The container belt dryer from Hans Binder is not just housed in a container – the container itself is the drying system. The shipping container serves as both the structural frame, housing, and air distribution module. Depending on the application and product requirements, the container can be shortened, extended, combined, or stacked.

Advantages at a glance

Easy Transport

Thanks to standard container dimensions, the container belt dryer can be easily transported by flatbed truck, train, or ship to its destination – ideal for international projects.

Maximum Flexibility

Whether for expansion, relocation, or adaptation – the modules can be adjusted at any time without compromising quality or performance.

100% Weather Resistance

The container belt dryer is the world’s first belt dryer that brings its own building. Robust and weatherproof, it operates reliably both indoors and outdoors.

Quick Commissioning

Prefabrication and testing in the factory ensure installation within a few days – minimal effort, maximum efficiency.

Exterior:

Flexible. Compatible. Versatile.

Maximum Flexibility

Custom designs adapt to all industries and drying requirements.

Adaptable Modular Construction

The modules are built to customer specifications and are always expandable.

Perfect Compatibility

Upstream and downstream peripheral modules can be easily integrated – depending on the application area.

Interior:

Efficient Technology for Perfect Drying

Optimal Airflow

Airflow from top to bottom ensures uniform drying.

Secure product handling

A heat-resistant specialty fabric belt gently transports the material through the dryer.

Uniform product feed

Flexible feed and dosing units, such as a twin distribution screw or scraper floor, ensure even distribution of the wet material.

Details:

Thoughtful extras

Corrosion protection

The interior and exterior cladding are corrosion-resistant and designed for long service life.

Energy efficiency

Waste heat from CHP, biogas, or industrial processes is efficiently used for drying.

Hygienic design

An integrated belt washing system simplifies cleaning and reduces downtime.

Process optimization

The turning mechanism accelerates the drying process and optimizes throughput times.

Versatility in every application

The flexible all-rounder:

Ideal for a wide range of applications and can be customized with suitable modules.

Efficient energy use:

Waste heat from biogas plants, combined heat and power (CHP) units, or industrial processes is specifically utilized for drying.

Suitable for large quantities:

With an extra-large feed hopper, it is ideally suited for industrial and agricultural bulk materials.

Wood in focus:

Especially suitable for wood drying – from wood chips to bark – with high throughput capacities.

Specialist for challenging materials:

Even demanding products can be efficiently dried thanks to flexible multi-belt guidance and optional heat recovery.

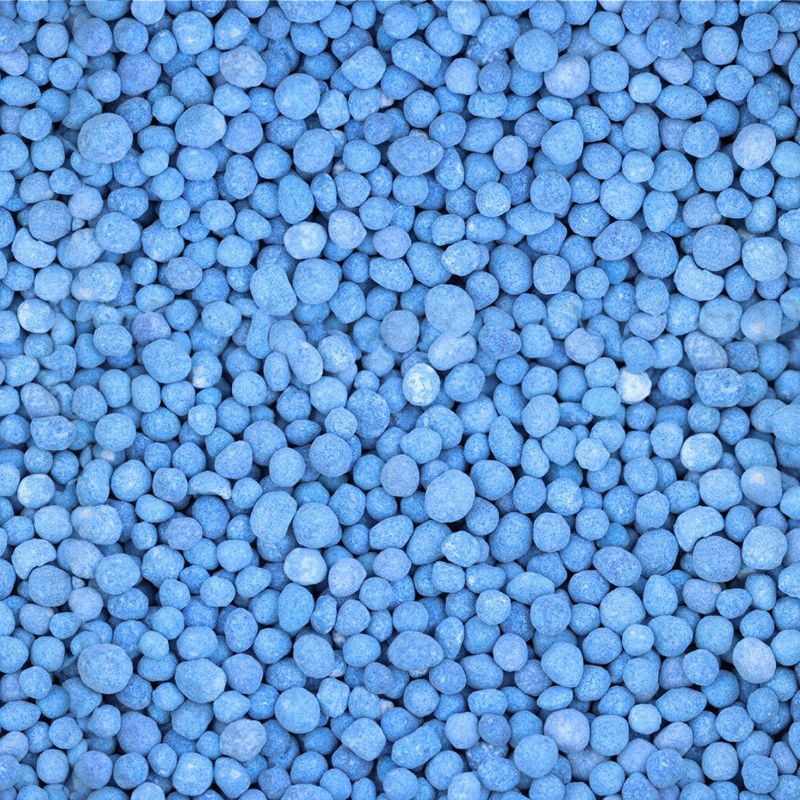

Optimized for fermentation residues:

Perfect for converting residual materials into fertilizer or other valuable products.

Compact solutions for fermentation substrates:

Even separated substrates can be processed efficiently and space‑savingly.

Recycling and valuable materials:

Especially suitable for drying recyclables and other valuable materials intended for further processing.

Modular belt dryer

Your dryer

grows with you

The container belt dryer is designed from the ground up to be modular. Each module can be individually planned, manufactured, and installed – perfectly suited to your current production volume.

When requirements change, the system grows with you:

- Expansion with additional container modules

- Adaptation to new products or capacities

- Integration of additional pre- and post-treatment peripherals

This flexibility makes the container belt dryer a future-proof investment. Whether as an entry-level solution or a high-capacity system, your drying technology can be easily expanded at any time without downtime or costly modifications.

For beginners and professionals alike

Frequently asked questions about the modular belt dryer

A container belt dryer is a fully functional belt dryer in which the shipping container itself serves as the structural frame and housing. It is modular, weatherproof, and mobile – ideal for changing locations and flexible production requirements.

It does not require a separate building, is more cost-effective to purchase, and can be quickly relocated or expanded thanks to its design.

It can be used for biomass, wood, recyclable materials, sewage sludge, animal feed, agricultural products, and many other materials.

Since the dryer is delivered prefabricated and tested, it is usually ready for operation within a few days.

Yes, it can utilize waste heat from biogas plants, CHP units, or industrial processes. Alternatively, direct or indirect heating systems can also be integrated.

The dryer is fully weather-resistant and can be operated outdoors without the need for an additional protective building.