Products

Belt roasters

SWEET OR SAVOURY?

Premium roasting

for gourmet flavor

Whether hazelnuts or walnuts, pumpkin or sunflower seeds – each product has its own characteristics. Belt roasters from Hans Binder engineering feature a smart design with separate, individually heated process zones that deliver excellent, uniform roasting results. We truly have many years of experience under our belts. Careful engineering and high-quality manufacturing ensure that our belt roasters are low-maintenance and highly efficient while conserving resources.

ADVANTAGES:

- Every zone individually heatable

- Maximum energy saving

- Optimum energy utilization through direct drive fans

- Intelligent roasting process control

- Consistent product quality

- High profitability through maximum air recirculation

Nuts

Seeds

Bread

Sugar beets

Roasting and cooling in a single unit

Innovative technology

The belt roaster consists of individually controlled process zones. Separate temperature adjustment for each zone ideally adapts the roasting process to your products, allowing you to achieve the desired roast, color and texture for each product. The design of the individual chambers ensures an evenly controlled air flow across the entire width of the conveyor belt. Each system is custom-designed and adapted to the existing space and facilities.

Optimum temperature

Roasting and cooling in one – an easy task with belt roasters from Hans Binder engineering. Using ambient air or active cooling, the roasted products are cooled to the right temperature for further processing directly after the roasting stage.

Maximum efficiency

Energy-efficient components such as direct-drive recirculation fans, ventilation and exhaust fans ensure optimal use of energy. The heat recovery system captures the energy released during product cooling so that it can be reused to heat the air supplied to the belt roaster. Fully insulated drying chambers ensure minimal heat loss and low operating costs.

Hygienic design

The system is made of stainless steel, which facilitates cleaning and increases the service life while lowering the risk of contamination with germs and bacteria. Tilted surfaces in the entire interior of the belt roaster and separate doors in each chamber provide optimum access and make cleaning even easier.

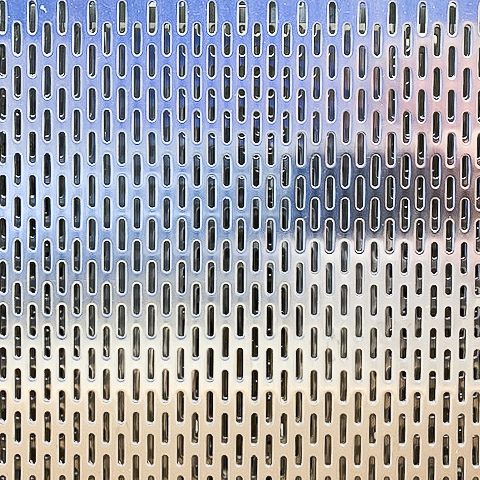

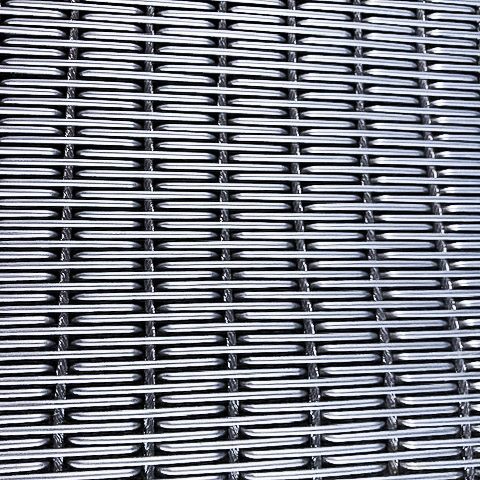

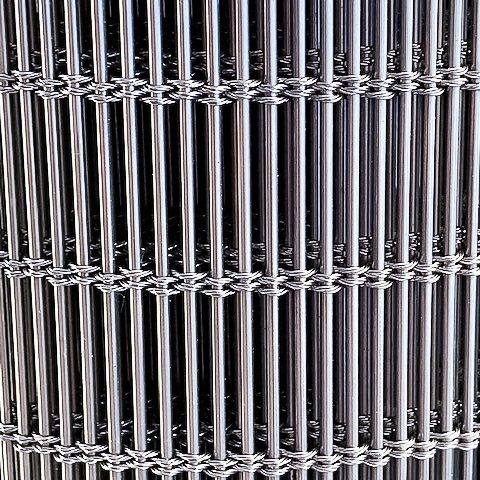

The right drying belt for every product

Depending on their size, flow properties and dwell time, products need belts of a specific size and surface structure to deliver uniform roasting and consistently high flavor and quality.

DRYapron

DRYpin

DRYrod-mesh

Delicious, crunchy, irresistible. With custom solutions that are right for each product.

Application

Individual solutions for many industries

Foodstuffs

Chemical products

Animal feed