Products

Processing lines

fresh, dry or granulated:

Our processing lines supply the perfect end product

Technically sophisticated processing lines, perfectly tuned to requirements, guarantee that the same high quality standards will be preserved throughout the production process. For processing fresh and dry products, and for granulation, the upstream and downstream lines are the perfect complement to any Hans Binder drying system. They, too, are designed individually according to product requirements and installed at the customer’s premises. We call it High-Tech from a single source.

All in one line – from fresh product to end product

Contact us for your individual processing line!

Fresh products

As gentle as possible

When processing fresh products, it is critical to treat them as gently as possible, in order to preserve the vitamins and flavors. Hans Binder fresh lines combine innovative technology and product-specific experience, so that no valuable ingredients are lost on the route from goods reception to washing and peeling.

- Reception, provisioning and dosing

- Removing extraneous material

- Sorting

- Washing in one or more procedures

- Intermediate dosing

- Cutting

- Re-washing (if necessary)

- Surface treatment or blanching

Fresh product processing examples

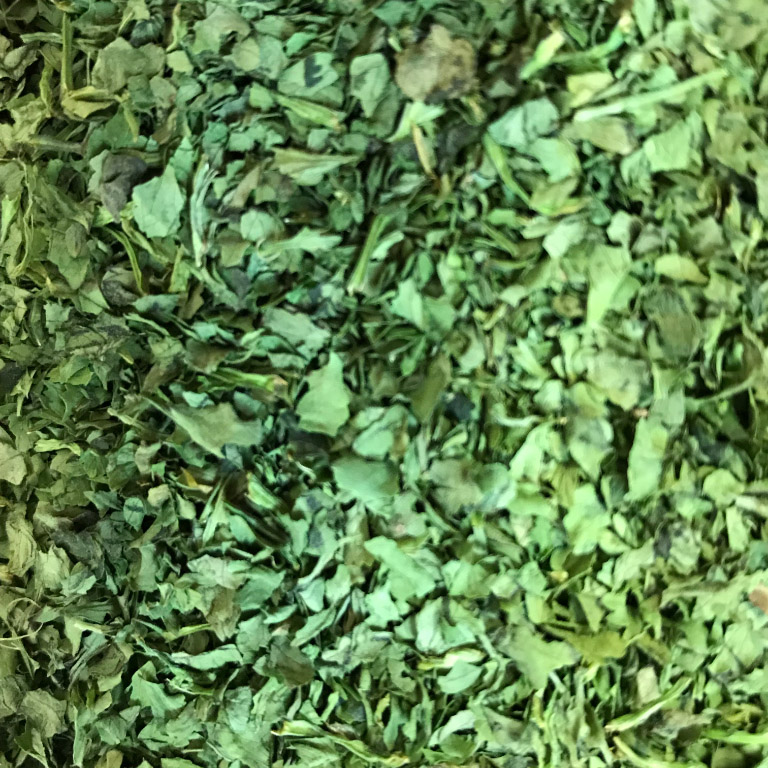

Leaf line

up to 3000 kg/h

Leaf parsley, spinach, dill

Root vegetables

up to 6000 kg/h

Carrots, parsnips, potatoes, beetroot

Vegetables

up to 5000 kg/h

Onions

Spices

up to 5000 kg/h

Capsicum, Chili

Fruit

up to 1500 kg/h

Apples

Dry product

Optimal cycle times

The precision and perfection of the individual work steps defines the quality of the dried product that leaves the belt at the end. Drying lines from Hans Binder engineering shred, sort, sift and pack every product with the utmost care and efficiency – and in accordance with the demands of the highest goods classes.

- Shredding

- Sorting

- Classification by size and/or color

- Packing

Dry goods processing examples

Leaf line

225 or 450 kg/h

Leaf parsley, spinach, dill

Root vegetables

up to 600 kg/h

Carrots, parsnips, potatoes, beetroot

Vegetables

up to 600 kg/h

Onions

Spices

up to 600 kg/h

Capsicum, Chili

Fruit

up to 600 kg/h

Apples

Granulation

Maximum time-saving

Hans Binder engineering has perfected granulation: Individual time-consuming process steps are combined into one smooth process sequence in which powder or granulate dry products are generated in the desired grain size. Mixing, dosing, shredding, screening and packing – a Hans Binder line performs these work steps in one pass.

- Mixing and dosing

- Shredding

- Screening into different groups

- Treatment of exhaust air

Granulate processing examples

Leaf line

up to 1000 kg/h

Leaf parsley, spinach, dill

Root vegetables

up to 1000 kg/h

Carrots, parsnips, potatoes, beetroot

Vegetables

up to 1000 kg/h

Onions

Spices

up to 1000 kg/h

Capsicum, Chili

Fruit

up to 1000 kg/h

Apples

Application

Individual solutions for many industries

Foodstuffs

Chemical products

Animal feed